Self-supporting glass railings- the weightlessness of a frameless structure

Balustrades and railings made of safe transparent glass are one of the most trendy solutions in modern interior design. When installing a self-supporting railing, glass panels are attached directly to the base (floor, edge of partition, etc.) using a metal clamping profile (inlay), point fasteners or other fixing elements, forming a safe protective barrier without unsightly supports that “cut through” the railing , profiles, balusters and racks. Since in such enclosing structures glass is a supporting element, according to technical standards, the use of laminated 12-30 mm tempered glass is the only acceptable option. Frameless enclosing structures do not take up useful space and create the best conditions for enjoying the surrounding panoramic view.

There are 3 ways of fastening of self-supporting glass railings to the base:

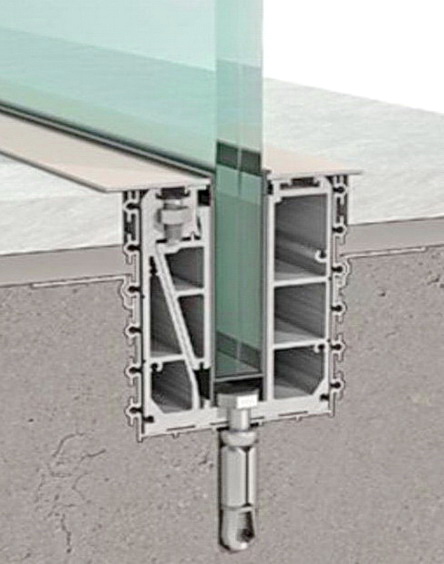

1. Fastening to clamping profile (inlay)

Self-supporting glass railings can be mounted in two types of clamping profiles (rails): hidden and open ones. It is natural that the hidden type of fastening is more popular, since the base of the glass is firmly fixed in the clamping profile, thus, there are practically no visible metal elements in the structure of the glass enclosure. Looking at such a glass enclosure creates the illusion of glass “floating” in space. The clamping profile can be installed in the floor or attached to the end of another design. The height of such glass railing is usually 900 mm. All-glass railings with hidden and open fasteners, in the place where the glass sheet is attached to the clamping profile can be decorated with:

“GlassPro” also offers a more stylish and reliable option that does not require additional decoration – a clamping profile made of high quality anodized aluminum. Advantages of anodized aluminum clamping profiles:

|

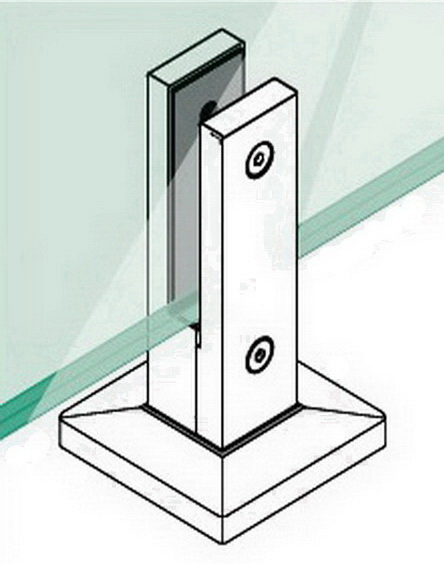

2. Mounting in stand-holders (glass railing with clips)

→ ➔ the impossibility of making a slot in a finished capital structure for installing a tire profile; → ➔ increased risk of installation on precise attachments to the edge of the partition in cases of large elevation differences or unfavorable weather conditions in the installation area. In this case, a clip-on glass railing becomes the only possible option for using a self-supporting frameless glass railing. Another advantage of fastening to stand-holders is the ability to install a glass railing on any finished surface and coating without damaging its integrity and without requiring additional installation work. A wide range of such fasteners allows the designer to make the project unique by selecting the necessary:

The preliminary decision regarding the number and type of glass clamps must be made by the design engineer, who calculates the size and weight of the structure and the wind load on the glass railing. |

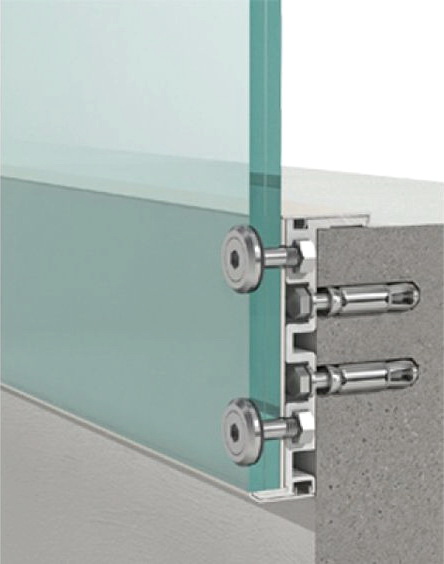

3. Point attachments to the edge face of various types of capital structures: overlap, parapet, staircase (without using a profile)

The scope of application of point mounts is quite wide:

|

Self-supporting glass railings can be made with or without handrails.The advantages of self-supporting railings with handrails include:

Handrails are not often used: → in places where additional loading (leaning) on the self-supporting glass railing must be avoided in order to ensure safety:

→ for an aesthetic purpose, for maximum “lightening” of the structure and its visual weightlessness and transparency:

→ in places where the height of the fence exceeds the standard, which basically eliminates the need for handrails. If a decision is made to use a handrail in a structure of this type, then in the absence of other metal elements, it can be mounted onto: metal holders

round on external mounts on the top edge of a glass panel

п-shaped handrail with slot on the top edge of a glass panel

round handrail with slot At your request, “Glaspro” can install handrails of various shapes on the glass railing: round, square or rectangular, made of various materials:

|

Choose model of self-supporting glass railing:

GS-01

Fastening to profile

GS-02

Fastening to rack holder

GS-03

Point mounts

TM

TM

Unlike an installation to a clamping profile, where the glass seems to “grow” out of the ceiling, this type of installation implies the presence of visible metal elements for fastening the glass sheets, while maintaining the feeling of weightlessness and transparency of the structure. The use of such an installation system, in addition to the design wishes of the architect and the customer, may be due to:

Unlike an installation to a clamping profile, where the glass seems to “grow” out of the ceiling, this type of installation implies the presence of visible metal elements for fastening the glass sheets, while maintaining the feeling of weightlessness and transparency of the structure. The use of such an installation system, in addition to the design wishes of the architect and the customer, may be due to:

If you want to decorate your interior in a modern and concise style, then the self-supporting point-mounted glass railing will be the best choice. Point fixings for the installation of safe glass self-supporting rails allow you to fix the glass sheet at several points without additional stands and racks, balusters and railing profiles, thus eliminating the need for bulky fixing fittings. To install such a railing, holes of the required size are drilled in the glass. The number of such holes and fasteners is determined by the dimensions of the glass sheet, and the place and scope of the structure. Holes are drilled in the glass (10-12 mm) even before it is tempered in an oven and lamination process.

If you want to decorate your interior in a modern and concise style, then the self-supporting point-mounted glass railing will be the best choice. Point fixings for the installation of safe glass self-supporting rails allow you to fix the glass sheet at several points without additional stands and racks, balusters and railing profiles, thus eliminating the need for bulky fixing fittings. To install such a railing, holes of the required size are drilled in the glass. The number of such holes and fasteners is determined by the dimensions of the glass sheet, and the place and scope of the structure. Holes are drilled in the glass (10-12 mm) even before it is tempered in an oven and lamination process. Glass is a material that can be affected by various environmental factors (heating, cooling), especially when used in external structures. For this reason, point fixings are installed in such a way that the glass can move relative to the fixing elements within a certain range. To avoid direct contact between glass and fixtures, special spacers and bushings made of elastic materials are used. Point fixings for glass enclosures can be made in different sizes and, usually, in stainless steel with a gloss or satin finish. The appearance of such fasteners is so versatile that they often go well with the design of any other fittings used for glass railing, and perform not only a functional, but also an aesthetic function. In some cases, connectors and fasteners can be covered and masked with decorative elements.

Glass is a material that can be affected by various environmental factors (heating, cooling), especially when used in external structures. For this reason, point fixings are installed in such a way that the glass can move relative to the fixing elements within a certain range. To avoid direct contact between glass and fixtures, special spacers and bushings made of elastic materials are used. Point fixings for glass enclosures can be made in different sizes and, usually, in stainless steel with a gloss or satin finish. The appearance of such fasteners is so versatile that they often go well with the design of any other fittings used for glass railing, and perform not only a functional, but also an aesthetic function. In some cases, connectors and fasteners can be covered and masked with decorative elements.