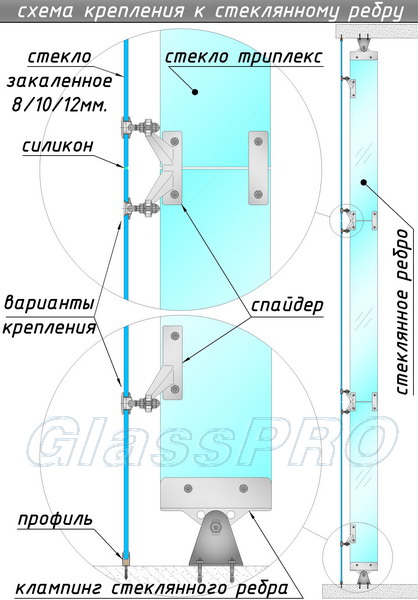

Mounting of “spider” glazing onto glass fins:

This assembly diagram of the “spider” glazing structures forms the following sequence:

glass → hinge → bracket → glass column (fin) (see picture) ↓

The most recent and actively developing system of mounting “spider” structures. Thanks to the development of technologies for the production and processing of glass, it became possible to create load-bearing glass columns up to 8 m long (solid) and up to 80 m (composite). This system is fundamentally different from the others in that it uses glass not only to fill the opening, but also performs a load-bearing function, breaking stereotypes about its fragility and vulnerability. Such opportunities were preceded by the development of XL-Glass (extra-dimensional glass), glass lamination with EVA film (which has better adhesion and strength in the composition of triplex), as well as a number of tests combined with specialized fittings from manufacturers like DORMA, SADEV, OXIDAL, SEVAX etc.

In this system, the proportion of glass used in relation to other materials is maximized. Even so, the structure retains its reliability, durability and safety. Moreover, due to the fact that both the supporting substructure and the elements for filling openings are made of glass, all the components have similar coefficients of thermal expansion. This makes it possible to minimize the joint distances between adjacent glass or glass units, and ensures stable operation of the system for a long time.

Comparing the installation concept of “spider” glazing on glass fins with other options (on capital structures, on metal posts or cable-stayed), we can highlight the following main advantages and disadvantages:

Advantages:

- uniqueness and originality of design;

- the maximum possible transmission of natural light and visual openness of the interior;

- durability and stability of the system in operation;

- the ability to create complex and non-traditional architectural formsli>

Disadvantages:

- complex design and installation;

- relatively high cost;сть;

- difficulty matching with other structural elements of the building: interfloor overlaps, adjacent internal partitions, etc.

![]()

TM

TM